Our Competence: Matchless Quality in Sheet Metal Processing

At MEZ, we are experts for machine housings, compact cabins and complex sheet metal components of any kind. Our know-how, an in-depth understanding of our customers’ requirements and our eye for detail let us act as a one-stop shop for intricate metal enclosures and assemblies made of thin sheet metal. We support our customers all the way – from prototype to series, from development to production to assembly.

Working in mechanical engineering, you place high demands on the efficiency and performance of your systems. These demands need to be reflected in precisely fitting enclosures and protective cladding. You need a partner who can implement even your most complex requirements with pinpoint accuracy. No matter your industry: We are this partner.

We develop solutions in line with latest guidelines and standards. For instance, we meet your requirements for laser or noise protection as well as food-safe use cases. With decades of experience across all areas of metal processing, we do not only reliably supply machine housings of the highest quality, we also advise you on how your ideas can be realised in the best way available for sheet metal.

From the very first sketches, our engineers work closely with production. This ensures that we are able to realise even complex sheet metal assemblies both flexibly and economically. We not only optimise your performance, but also your costs. And should you require it, we accompany your project right up to on-site installation.

Our Goal: Providing Quality Down to the Last Detail of Your Casing

Whether steel, stainless steel or aluminium construction: our products stand for first-class quality. Expert metal and sheet metal processing are our top priority. Our team are specialists in sheet metal assemblies and machine cladding as well as complex steel and welding constructions. They are committed to perfection. This is reflected in our flawless welded seams and precise interfaces, as well as in the clean lines that characterise our designs. After all, we offer detailed workmanship not only at the functionally relevant points, but also wherever it is of visual importance. Needless to say, MEZ is certified according to ISO 9001:2015 and is a certified welding company according to ISO 3834-2:2021. We secure our high quality standard through regular internal audits.

Modern Production Technologies Designed for the Most Sophisticated Sheet Metal Processing

Every part we manufacture must meet the same standard: the highest. That’s why, in addition to our qualified specialists, we rely on modern production facilities to be able to reliably fulfil all your requirements:

- A fibre laser from Trumpf enables the processing of steel, stainless steel, aluminium, copper and brass with highest precision.

- Bystronic bending presses and a state-of-the-art round bending machine ensure precise bending, folding and rounding processes.

- A cutting-edge deburring machine allows for maximum production quality and product safety.

- Various welding techniques for stainless steel, aluminium and black plate are part of our employees‘ standard skill set.

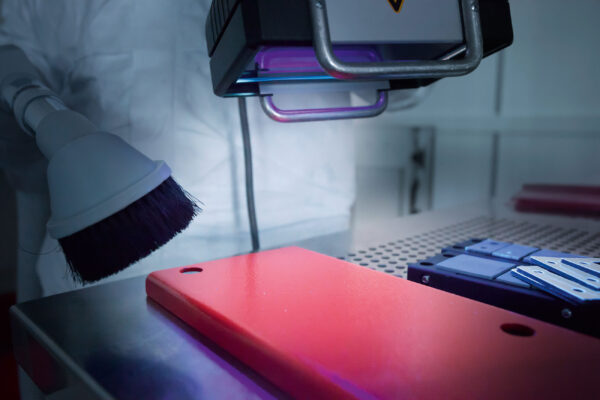

- We comply with the special requirements of the semiconductor industry with our own cleanroom for our machine claddings.